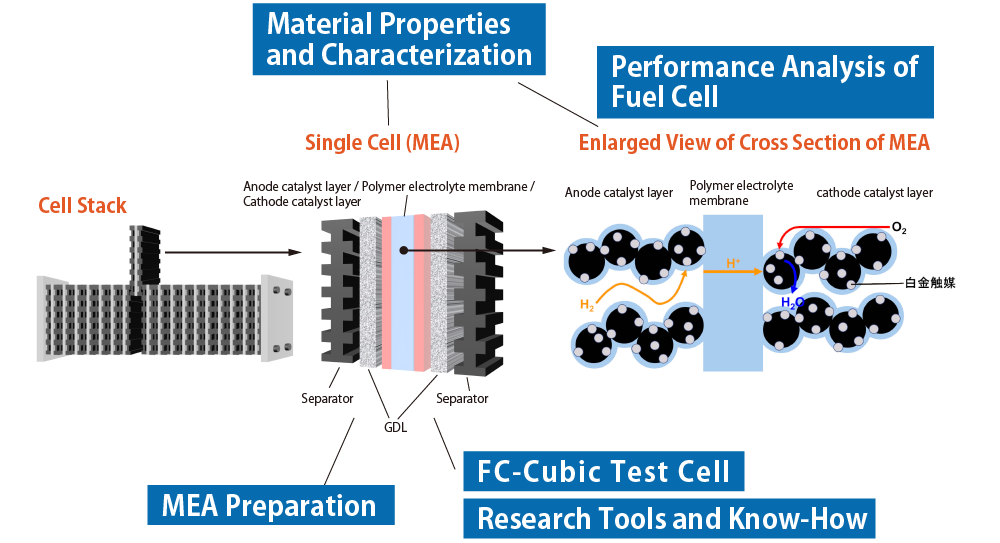

We introduce the fuel cell evaluation technology of FC-Cubic. A general cell configuration of a polymer electrolyte fuel cell installed in such as fuel cell vehicles is two catalyst layers in which hydrogen and oxygen react respectively, an electrolyte membrane, gas diffusion layers (GDL), and separators. This minimal configuration is a single cell.Actual fuel cell vehicles are equipped with stacked cells which a lot of the single cells stack, while we are mainly studying the performance of the catalyst and the polymer electrolyte membrane using fuel cells in a single-cell state. To evaluate a fuel cell in a power generation test, we assemble an test cell by preparing a membrane electrode assembly (MEA) consisting of the catalyst layers, the electrolyte membrane, and the GDL, which are described above. We introduce these MEA preparation technologies and fuel cell evaluation technologies for each item.

MEA Preparation

Fuel cell performance of the catalyst is evaluated by actually conducting power generation tests. We incorporate the membrane electrode assembly (MEA), which consists of the catalyst layers, the polymer electrolyte membrane, and the gas diffusion layers, into the test cell in power generation tests. Therefore, each process is required to produce MEA from catalyst powder. At FC-Cubic, we have a consistent system from preparation of catalyst ink to it of MEA.

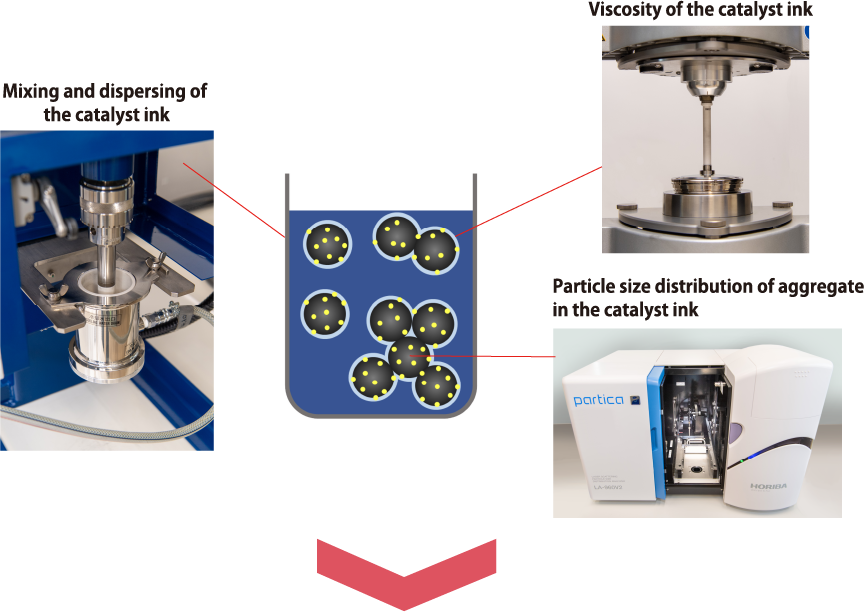

Catalyst Ink Preparation

The catalyst ink is prepared by uniformly mixing the fuel cell catalyst, ionomer and solvent. The viscosity of the ink and the aggregation of the catalyst are controlled to minimize the impact on the power generation performance.

Ink Coating Process

The catalyst ink is applied to the sheet with a uniform thickness using a blade-type or a spray-type coating device. In the spray coating process, the catalyst layer can be directly applied to the polymer electrolyte membrane. The surface morphology of the catalyst layer after coating is observed with a microscope to check for thickness, cracks and so on.

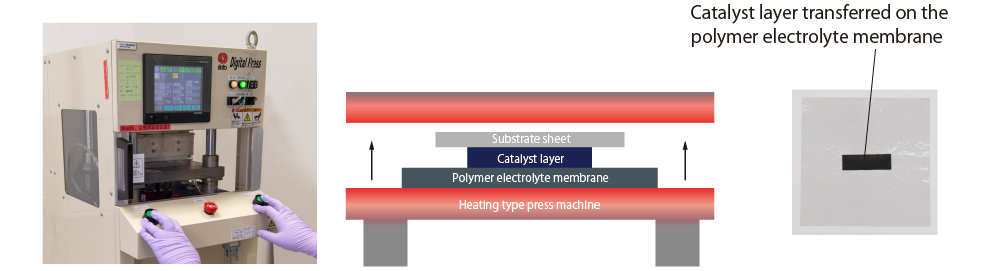

Transfer Process

In transfer process, the catalyst layer coated on the sheet is transferred to the polymer electrolyte membrane. The catalyst layers of anode and cathode are transferred to the polymer electrolyte membrane, respectively. Furthermore, the MEA is finally completed by laminating the subgasket and gas diffusion layer (GDL) by thermocompression bonding.

Performance Analysis of Fuel Cell

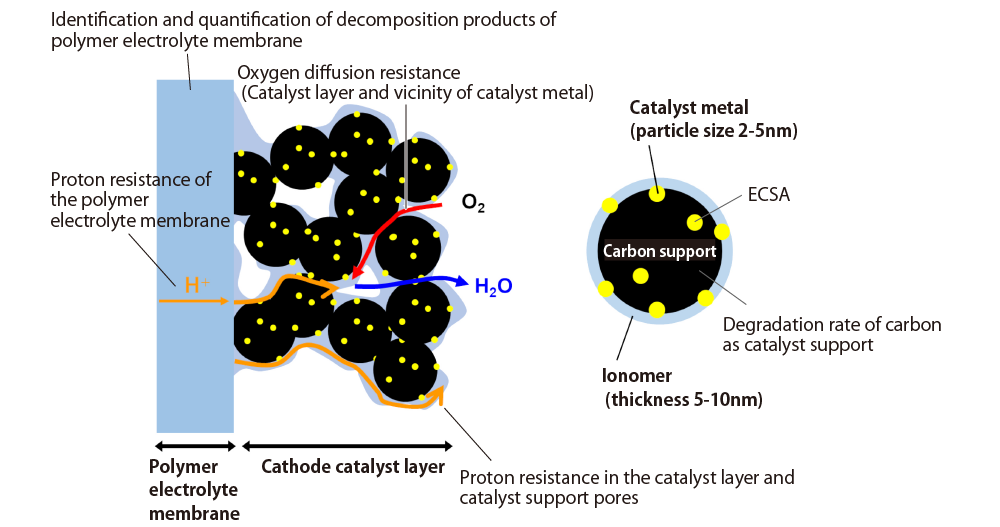

Through power generation tests using a fuel cell evaluation equipment, we can obtain not only catalyst metal specific surface area and catalyst activity, but also various information on MEA. Furthermore, by incorporating mathematical models such as the 1-D model (transmission line model), it is possible to concretely understand the causes of power generation loss. Analysis of drain water and exhaust gas during the durability tests provides information on degradation factors of the catalyst metal, the polymer electrolyte membrane and carbon catalyst supports.

Material Properties and Characterization

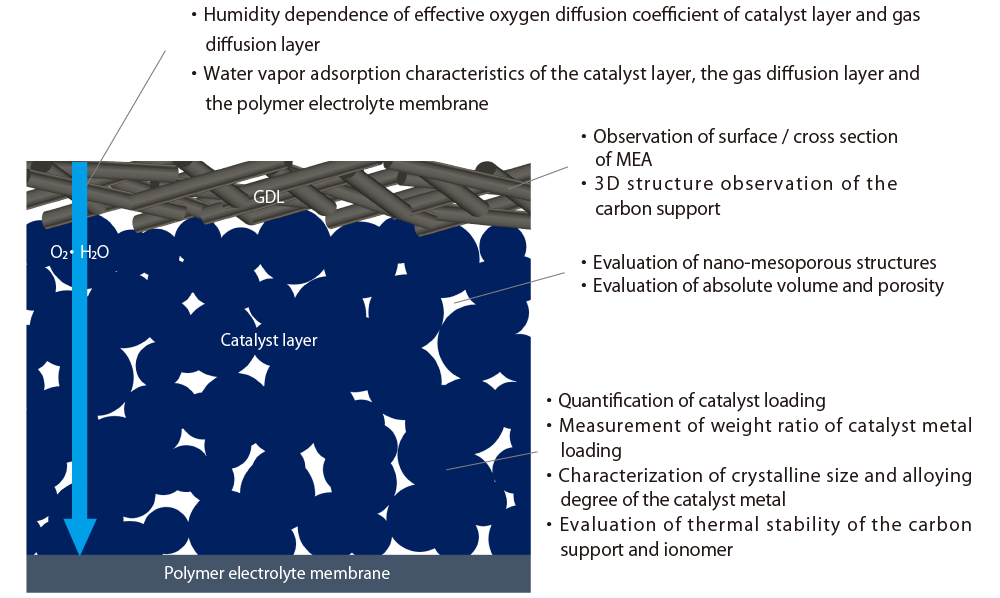

Catalyst Layer

Evaluation

Various evaluations and observations are conducted on the catalyst layer in the MEA.Structural observation by scanning electron microscope (SEM) and transmission electron microscope (TEM) and nitrogen gas adsorption measurement can be used to evaluate nano-macropores in the catalyst layer.Thermogravimetry (TG) and X-ray fluorescence spectrometry (XRF) can also be used to quantify the amount of catalyst supported and the catalyst metal in the catalyst layer, and various evaluation methods are used to evaluate oxygen diffusion and steam adsorption characteristics in the catalyst layer.

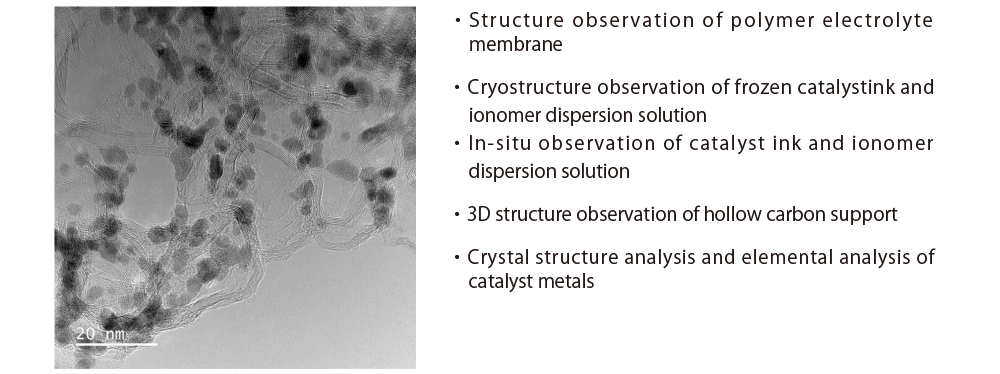

Catalyst and Electrolyte

Membrane Observation

Scanning transmission electron microscopy allows observation of various structures such as catalysts and polymer electrolyte membranes. The 3D imaging function can provide a three-dimensional structure information of hollow carbon support with complex porous structures. Polymer electrolyte membranes and ionomers in various states can be observed using specific holders for cryo and liquid samples.

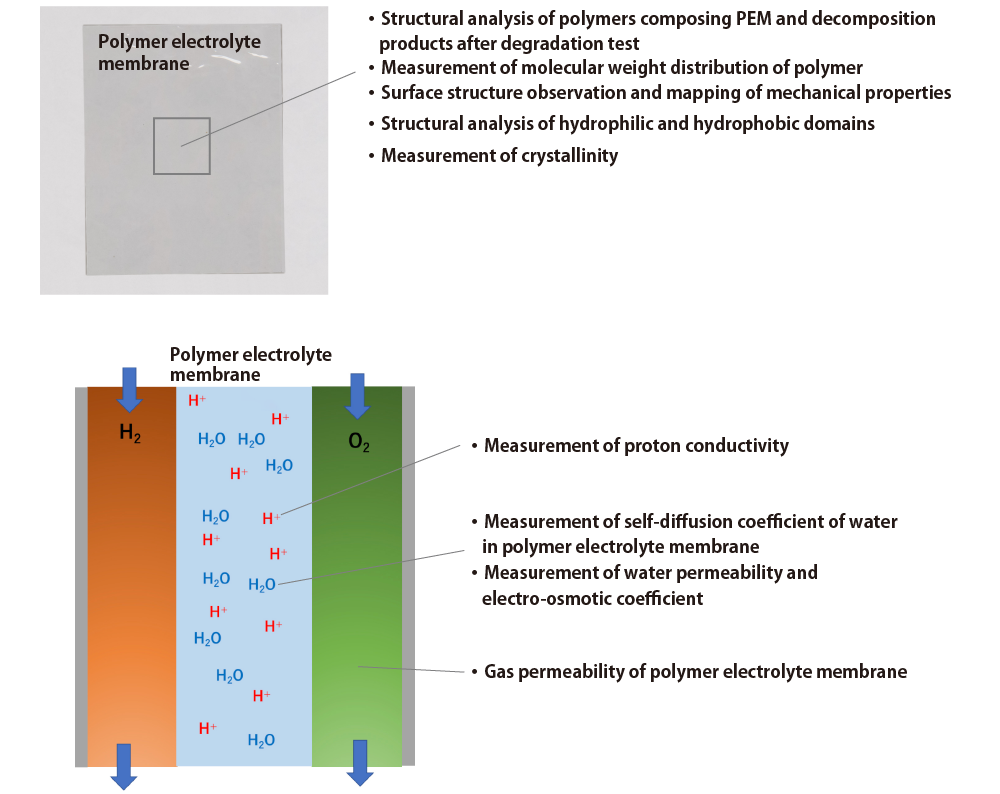

Characterization of PEM

Based on various information such as the molecular structure and molecular weight of polymer electrolyte membranes, various evaluations and analyses are conducted to obtain the degradation behabior of polymer electrolyte membranes after testing. Material transport properties such as the movement of H+ and water in electrolyte membranes which significantly impacts on fuel cell performance, gas permeability, and mechanical properties such as tensile tests and dynamic viscoelasticity are also evaluated.

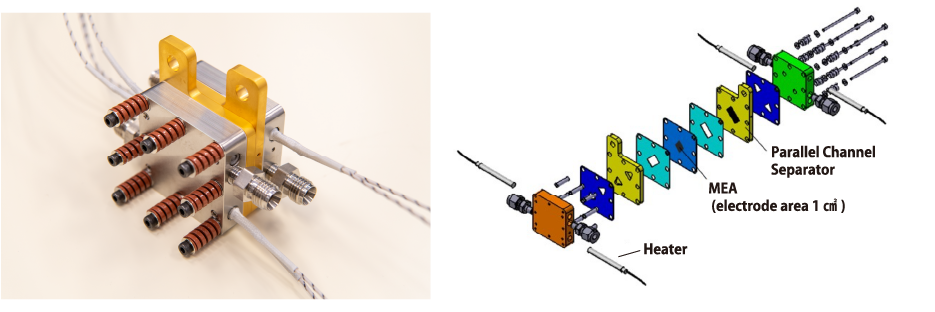

FC-Cubic Test Cell

We have developed a new type of test cell that integrates the know-how of fuel cell evaluation in industry. The spring is designed to moderate the overload during thermal expansion by controlling the surface pressure, and the electrode area of 1cm2 reduces the amount of catalyst and electrolyte membrane used compared to conventional evaluation cells. This cell also takes into account assembling and measurement stability such as cell size and cross-flow design. For more information, please contact us from "contact us" or send a message to fc3cell@fc-cubic.or.jp.

Research Tools and Know-How

In other countries, industry-academia-government collaboration in fuel cell development research is accelerated by the country or region. At the same time, we will start to provide industry’s R&D tools and know-how on fuel cells to academia to promote industry-academia-government collaboration in our country as a measure to stimulate exchanges of technology and human resources between industry and academia. FC-Cubic will serve as a bridge between industry and academia, contributing to the activation of Japan’s fuel cell industry through industry-academia-government collaboration. This information is limited to those in academia in Japan who wish to be provided it. For more information, please contact us from “contact us” or send a message to Info-fc3@fc-cubic-event.jp. For public information, please refer to “1. Research and Development Tool/Know How Sharing” in the 5th FC-Cubic Open Symposium Materials Open to the Public | FC Cubic Open Symposium (fc-cubic-event.jp).